Integrating Digital into the Industrial Value Chain

Showcase HMI 2017

Integrate digital aspects into the industrial value chain

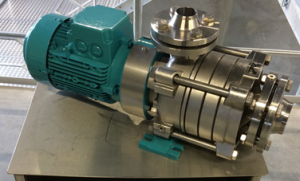

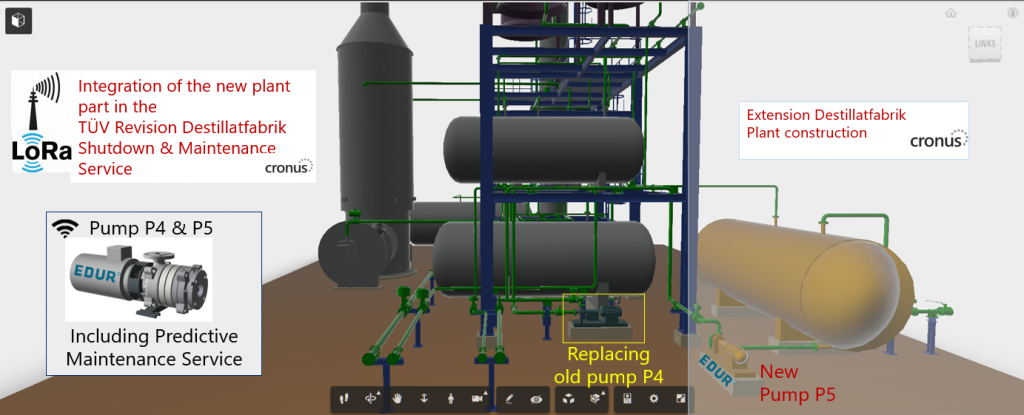

- Topic: Digital transformation across company borders on a cloud-based platform. The entire value chain can be represented digitally: from producing a pump of the company EDUR-Pumpenfabrik, to intelligent tracking on construction sites during installation, to predictive maintenance service as an example of smart assets.

- By using business apps on the cc|smart cloud platform and making use of latest IoT technologies to track the position and sensor data of the pump (smart asset)

- In collaboration with our cooperation partners

- Companies participating in the showcase:

- EDUR-Pumpenfabrik (pump supplier)

- Destillatfabrik AG (process plant operator)

- Cronus AG (plant engineering and industrial service provider)

- Stork Umwelttechnik (virtual industrial park operator)

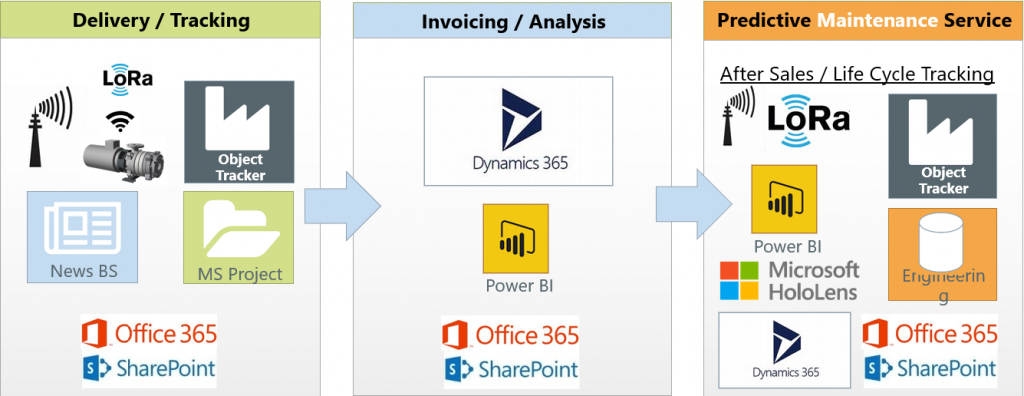

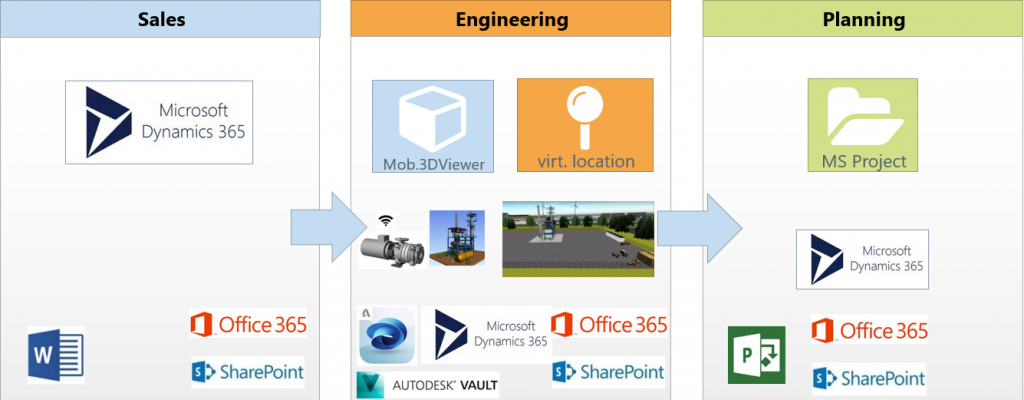

Business apps and IoT products are used use on the cc|smart cloud platform

MS Dynamics 365 Business Edition (formerly Microsoft Dynamics NAV) ERP in the cloud MS Office 365 (collaboration in the cloud) Business apps on the cc|smart cloud platform based on Microsoft Azure

- cc|vendor & contractor portal (web portal to interact with external partners)

- cc|safety instructor (mobile plant, safety, and work instructions)

- cc|object tracker (mobile tracking of objects, activities & lifecycle data)

- cc|team site (Team Collaboration Site on Office 365)

- cc|project online (MS Project in Office 365)

- cc|pmo (multi-project management in Office 365)

- cc|BI-Cockpit (Business Analytics via Power BI in the Cloud)

- A 360 (mobile 3D viewer of Autodesk in the cloud)

LoRa IoT tags & sensors

- LoRa® pump sensor of telent/Netzikon (incl. interface to cc|object tracker)

- cc|object tracker with LoRa® asset tags of Bosch (incl. interface)

- cc|object tracker with LoRa® vehicle/asset-tracking tag of telent/Netzikon (incl. interface)

Virtual Reality & Augmented Reality

- Site information system of Fraunhofer IFF (virtual industrial park)

- MS HoloLens (3D – VR glasses with hologram technology)

Integrate digital aspects into the industrial value chain

HMI scenarios – with actors in the process: 0) the operator of a production plant in an industrial park (Destillatfabrik AG) wants to expand its existing process plant and must include this expansion in the framework of a shutdown for general repairs. To achieve this, an external plant construction / plant service company (Cronus AG) is commissioned and pumps are ordered by a pump manufacturer(EDUR-Pumpenfabrik). For the work on production site, the operator provides all the necessary information and role-based mobile apps in a cloud-based contractor portal to interact with its external partners. The operator want to make sure that all those involved in its system are working safely. It provides the Safety Instructor app for the safety instructions for staff. It tracks critical equipment, such as, for example, the new pump P5 using Object Tracker. (1) a pump manufacturer (EDUR-Pumpenfabrik) gets the contract to build and deliver a special pump P5. The Object Tracker is used to find out about the status of the pump P5 and the interaction of its components whenever needed. This special tracker can monitor heterogeneous objects and display their respective status. (2) via integrated sensors on its pump, the pump manufacturer (EDUR Pumpenfabrik), receives information that pump P4 in the production plant will soon have a malfunction. It contacts the customer (Destillatfabrik AG) as part of its predictive maintenance order and supplies a replacement pump P4. The repair can take place within the framework of the scheduled shutdown for general repairs at the production plant. The mechanic of Cronus AG uses the Microsoft HoloLens on-site to see which malfunction is imminent for the pump or which parts need to be replaced.

Showcase CRONUS AG @ HMI 2017 – Plant construction & Shutdown & Maintenance Service

Showcase EDUR pumps factory @ HMI 2017 -Equipment manufacturer – predictive maintenance service